The announcement of 5 Million Electric Drives Produced is more than a production statistic—it represents a structural shift in how the global automotive industry is transitioning to electrification. For Volkswagen Group, this milestone reflects not just volume manufacturing success but technological maturity, platform efficiency, and long-term strategic commitment to electric mobility.

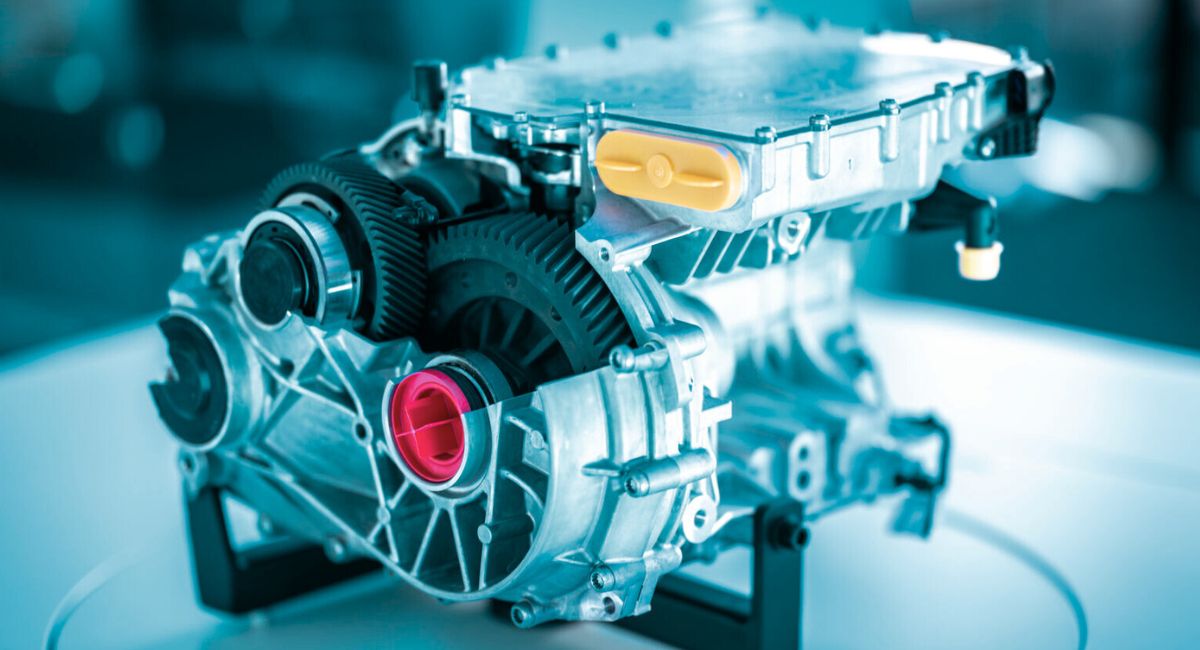

At the heart of this achievement lies the APP550 electric drive unit, a next-generation propulsion system designed to deliver greater power, efficiency, and scalability across multiple EV models. Quietly integrated into new electric vehicles, the APP550 is redefining what mainstream electric performance should feel like.

This is not just about numbers. It is about industrial evolution.

Why 5 Million Electric Drives Produced Is a Strategic Turning Point?

Reaching five million electric drive units is a critical inflection point for any automotive manufacturer. It signals:

- Industrial-scale EV manufacturing capability

- Proven supply chain stability

- Refinement of production quality standards

- Improved cost efficiency per unit

- Confidence in long-term EV demand

For Volkswagen Group, it confirms that electric propulsion is no longer experimental—it is foundational.

Electric drives are the core of any EV. Unlike traditional combustion engines, electric drive systems require precise integration of motor, power electronics, cooling systems, and transmission components. Achieving five million units means these complex systems are now being manufactured at levels comparable to traditional engines.

That shift changes everything.

Understanding the APP550 Electric Drive System

The APP550 is Volkswagen Group’s latest rear-axle electric drive unit developed for vehicles based on the MEB (Modular Electric Drive Matrix) platform.

It replaces earlier-generation motors and introduces significant technical improvements.

Core Specifications of the APP550

- Motor Type: Permanent Magnet Synchronous Motor (PSM)

- Peak Power Output: Approximately 210 kW (around 286 PS / 282 hp)

- Maximum Torque: Approximately 550 Nm

- Drive Layout: Rear-wheel drive (RWD)

- Integrated Components: Power electronics and transmission unit

- Cooling System: Optimized liquid cooling

- Efficiency Enhancements: Reduced electrical losses and improved magnetic materials

These specifications reflect a clear performance upgrade over earlier MEB motors while maintaining high efficiency.

Read more:- Top 10 DJI Drones to Buy in India in 2025 for Beginners Who Want Zero Regret?

How APP550 Improves Performance?

Higher Power Density

The APP550 delivers increased output without increasing physical size significantly. This higher power density enables:

- Faster acceleration

- Better high-speed performance

- Improved overtaking capability

For everyday drivers, this translates into smoother responsiveness and stronger mid-range acceleration.

Enhanced Thermal Management

Electric motors generate heat under high load. The APP550 integrates an optimized cooling system that ensures:

- Stable performance during long drives

- Reduced performance drop in hot climates

- Improved durability

This matters especially in markets with extreme weather conditions.

Efficiency Gains

One of the most important improvements is efficiency optimization. Through refined rotor and stator design, enhanced magnet materials, and improved inverter control, the APP550 reduces energy losses.

Better efficiency means:

- Extended driving range

- Lower energy consumption per kilometer

- More consistent real-world range performance

Efficiency is the silent hero of electric mobility—and this is where the APP550 truly shines.

Integration with the MEB Platform

Volkswagen’s MEB architecture is a modular EV platform that underpins multiple models across the Volkswagen Group portfolio.

The APP550 is specifically engineered to work seamlessly within this platform.

Benefits of Platform Integration

- Simplified manufacturing processes

- Lower production costs

- Cross-brand scalability

- Faster rollout of new models

The electric drive unit is produced in high-volume facilities and distributed across various markets. Because the architecture is standardized, production efficiency increases as volume scales.

This explains how reaching 5 Million Electric Drives Produced became possible.

Real-World Applications of the APP550

The APP550 is not a concept motor—it powers real vehicles currently on the road.

It supports:

- Mid-size electric SUVs

- Electric sedans

- Compact crossovers

- Global market EV variants

Rear-wheel-drive configuration offers balanced weight distribution and driving stability. The motor’s torque delivery is instant, creating a refined driving experience.

In practical terms, drivers experience:

- Smooth acceleration from standstill

- Reduced vibration

- Quiet cabin operation

- Strong regenerative braking response

These characteristics collectively improve daily usability.

Manufacturing Excellence Behind 5 Million Electric Drives Produced

Producing five million electric drives requires advanced manufacturing infrastructure.

Key elements include:

Automation and Precision Engineering

Electric motors demand tight tolerances in rotor alignment and magnetic assembly. Automated production lines ensure:

- High consistency

- Reduced human error

- Improved reliability

Vertical Integration

Volkswagen Group produces core electric drive components internally. This strengthens:

- Quality control

- Intellectual property ownership

- Supply chain security

Global Production Strategy

Production facilities are optimized for scale and distributed strategically across regions to meet demand.

Reaching five million units reflects not just product demand but manufacturing maturity.

What Makes APP550 Different from Previous Generations?

The evolution from earlier MEB motors to the APP550 includes:

- Improved stator windings

- Enhanced magnetic materials

- Upgraded inverter software

- Reduced internal friction

- Higher torque output

The result is a more powerful yet more efficient motor.

This combination of performance and efficiency defines next-generation EV propulsion.

Impact on EV Driving Range

Driving range remains one of the most critical decision factors for EV buyers.

The APP550 contributes to improved range through:

- Reduced electrical resistance

- Optimized power electronics

- Better energy conversion efficiency

While actual range varies depending on battery capacity and vehicle weight, the motor’s improved efficiency ensures better real-world consistency.

Range stability builds consumer trust.

Sustainability and Environmental Impact

Electric vehicles are often evaluated through lifecycle impact.

The APP550 supports sustainability by:

- Improving overall vehicle efficiency

- Reducing energy waste

- Supporting scalable electrification

Higher efficiency means fewer charging cycles over time. That indirectly reduces grid strain and long-term energy consumption.

Manufacturing scale also helps reduce per-unit production emissions through optimized processes.

The Broader Industry Implication

The milestone of 5 Million Electric Drives Produced signals a major transition in automotive engineering.

Traditional combustion engines required over a century to refine and scale globally.

Electric propulsion has reached industrial scale in less than two decades.

This acceleration suggests:

- EV technology is stabilizing

- Manufacturing learning curves are flattening

- Cost reduction is accelerating

For consumers, this means more reliable, affordable EV options.

Reliability and Durability Expectations

Electric motors generally have fewer moving parts than combustion engines.

The APP550 benefits from:

- Simplified mechanical architecture

- Reduced wear components

- Advanced cooling systems

Long-term durability improves ownership experience and reduces maintenance costs.

In real-world conditions, this translates to:

- Lower service requirements

- Fewer mechanical breakdowns

- Improved total cost of ownership

Reliability reinforces trust in electric mobility.

Why This Milestone Matters for Consumers?

When manufacturers reach multi-million production milestones, several positive outcomes follow:

- Improved parts availability

- Lower component cost

- Enhanced service network expertise

- Stronger resale value confidence

Consumers indirectly benefit from large-scale manufacturing success.

Five million electric drives indicate proven technology, not experimental engineering.

The Future Outlook of APP550 and Beyond

The APP550 represents a stepping stone.

Future developments may include:

- Higher power variants

- Further efficiency optimization

- Software-driven torque management improvements

- Integration with next-generation battery systems

As battery chemistry evolves, electric motors will also continue advancing.

The APP550 shows that electric propulsion innovation is far from complete.

Quietly Leading the Electric Transition

The achievement of 5 Million Electric Drives Produced is not just a milestone—it is a declaration of industrial transformation.

Through the APP550 electric drive unit, Volkswagen Group demonstrates that electric mobility is no longer an emerging experiment but a mature, scalable, and performance-driven reality.

What makes this shift remarkable is its subtlety. There was no dramatic revolution—only continuous engineering refinement, manufacturing discipline, and technological commitment.

And sometimes, that is how true transformation happens.

FAQs

What does 5 Million Electric Drives Produced mean?

It means Volkswagen Group has manufactured five million electric motor units for its electric vehicles. This milestone reflects large-scale EV production capability and technology maturity.

What is the APP550 electric drive?

The APP550 is a rear-axle permanent magnet synchronous motor developed for Volkswagen Group’s MEB electric vehicle platform. It offers improved power output, torque, and efficiency compared to earlier versions.

How powerful is the APP550 motor?

The APP550 delivers approximately 210 kW (around 286 PS) and up to 550 Nm of torque, offering strong acceleration and enhanced performance in compatible vehicles.

Does the APP550 improve driving range?

Yes. Its improved efficiency and optimized power electronics reduce energy losses, contributing to better real-world driving range depending on battery capacity.